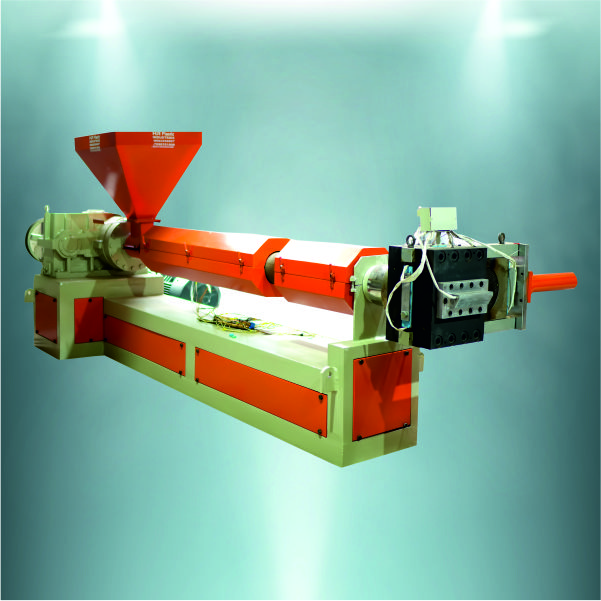

AUTOMATIC RECYCLING PLANT / DANA MAKING MACHINE

An automatic recycling plant / dana making machine efficiently transforms plastic waste into reusable pellets or granules. It incorporates advanced sorting, shredding, and extrusion processes, ensuring high-quality output suitable for various industries. This automated system enhances recycling efficiency, reduces waste, and supports sustainable manufacturing practices.

An automatic recycling plant equipped with a Dana-making machine is designed to efficiently convert waste plastic materials into reusable granules, known as Dana. The process begins with the collection of various types of plastic waste, which are then sorted, cleaned, and shredded into smaller pieces. These plastic fragments are fed into the recycling plant’s extruder, where they are heated and melted down.

The molten plastic is passed through a specialized filtration system to remove any contaminants or impurities, ensuring a high-quality end product. The purified plastic is then extruded through a die to form continuous strands, which are subsequently cooled and solidified. These strands are cut into uniform granules or pellets, commonly referred to as Dana.

The entire process is automated, with advanced sensors and control systems ensuring optimal temperature, pressure, and speed throughout each stage. This automation not only increases efficiency and output but also reduces manual labor and the potential for human error. The resulting Dana can be used in various manufacturing applications, contributing to a circular economy by transforming plastic waste into valuable raw material for new products. This sustainable approach helps reduce environmental pollution and conserves natural resources by minimizing the need for virgin plastic production.

|TECHNICAL SPECIFICATION

| PLANT MODEL | HRPI-90 | HRPI-100 | HRPI-110 | HRPI-120 | HRPI-130 | HRPI-140 |

|---|---|---|---|---|---|---|

| OUTPUT | 80-100 KG/hr | 100-130 KG/hr | 130-180 KG/hr | 180-250 KG/hr | 250-350 KG/hr | 350-450 KG/hr |

| MATERIAL NAME | LD, PP, HD ALL TYPE OF AGGLO PLASTIC MATERIAL, CHIPS | LD, PP, HD ALL TYPE OF AGGLO PLASTIC MATERIAL, CHIPS | LD, PP, HD ALL TYPE OF AGGLO PLASTIC MATERIAL, CHIPS | LD, PP, HD ALL TYPE OF AGGLO PLASTIC MATERIAL, CHIPS | LD, PP, HD ALL TYPE OF AGGLO PLASTIC MATERIAL, CHIPS | LD, PP, HD ALL TYPE OF AGGLO PLASTIC MATERIAL, CHIPS |

| SIZE | 90 MM | 100 MM | 110 MM | 120 MM | 130 MM | 140 MM |

| VENTED SCREW BARREL | EN 41 B WITH SPECIAL GAS NITRATING | EN 41 B WITH SPECIAL GAS NITRATING | EN 41 B WITH SPECIAL GAS NITRATING | EN 41 B WITH SPECIAL GAS NITRATING | EN 41 B WITH SPECIAL GAS NITRATING | EN 41 B WITH SPECIAL GAS NITRATING |

| GEAR BOX | 180 CD GEAR BOX (STANDARD COMPANY) | 200 CD GEAR BOX (STANDARD COMPANY) | 225 CD GEAR BOX (STANDARD COMPANY) | 250 CD GEAR BOX (STANDARD COMPANY) | 250 CD GEAR BOX (STANDARD COMPANY) | 275CD GEAR BOX (STANDARD COMPANY) |

| MOTOR | 25 HP | 30 HP | 40 HP | 60 HP | 75 HP | 100MM |

| CONTROL PANNEL | 8 | 8 | 10 | 10 | 10 | 10 |

| SCREEN CHANGER | 8” | 8” | 10” | 10” | 10” | 12” |

| CUTTER MACHINE | 6″” WITH 2 HP MOTOR | 6″” WITH 2 HP MOTOR | 6” WITH 3 HP MOTOR | 8” WITH 5 HP MOTOR | 8” WITH 5 HP MOTOR | 10” WITH 5 HP MOTOR |

| MIXTURE MACHINE | 12X21X12” -SIZE S.S. MATERIAL | 12X21X12” -SIZE S.S. MATERIAL | 12X21X12” -SIZE S.S. MATERIAL | 12X21X12” -SIZE S.S. MATERIAL | 12X21X12” -SIZE S.S. MATERIAL | 12X21X12” -SIZE S.S. MATERIAL |

| OPTIONAL DEVICE | DIE FACE CUTTER SYSTEM AUTOMATIC HOPPER LOADER TANK AGGLO MIXTURE MACHINE |

Filter Using Tags